By: Benjie Wells

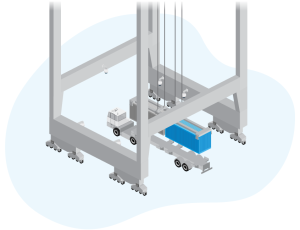

In the world of container handling at ports and terminals, efficiency, reliability, and accuracy are of the utmost importance. Optical Character Recognition (OCR) technology has revolutionized the industry, streamlining the process of capturing and recording container details. One of the most common areas to apply OCR is at STS Cranes at the waterside operations. In this blog, we will explore why having multiple cameras on an STS crane for Crane OCR is preferable to moving cameras.

Reliability through redundancy

One of the most compelling reasons for using multiple cameras on an STS crane is the inherent reliability that redundancy provides. When a single pair of moving cameras is employed, any malfunction or damage to one camera can have a significant impact on the OCR results. If one of these cameras malfunctions, it can disrupt the entire container capture process. This vulnerability to single-point of failures can lead to costly downtime and errors in data collection.

In contrast, the use of multiple, fixed cameras allows for built-in redundancy. When one camera encounters an issue, others seamlessly take over the capturing process. This ensures that even in the event of a camera failure, the OCR results will remain reliable. The continuity of operations will be maintained, minimizing disruptions and increasing overall efficiency.

“When one camera encounters an issue, others

seamlessly take over the capturing process.”

Comprehensive Container Coverage

Another compelling argument for using multiple cameras is the ability to capture every side of the container. With the CERTUS OCR Solution, multiple fixed cameras are strategically positioned to capture all sides of the container, as well as a top image and the terminal tractor roof for identification. Contrary to other vendors that offer 4 side container images only, this fifth top image is an important addition to the damage images, and so is the terminal tractor identification for automated hand-off between STS and Terminal Tractor

CERTUS Crane OCR also does not use spreader cameras to capture the top of the container. STS Crane spreaders are typically prone to abuse and therefore not well suited for installation of cameras over prolonged duration use. CERTUS setup also prevents the need for more sets of cameras for spare spreaders.

Enhance Durability

STS Cranes operate in challenging environments and the equipment must endure the rigors of container handling. CERTUS’ track record contains systems that are operational for over ten years! Because our system does not use moving parts, it is much less susceptible to wear and damage. This allows you to continue working without interruptions.

Seamless Integration

Our Crane OCR solution stands out for it seamless integration with horizontal transport. The hand-off process is automated, which means that identification of the terminal tractor ID is supported for every container transaction. This is a standard option and requires no extra camera’s. The automated hand-off makes the crane transactions faster and thus improves the cranes productivity.

The advantages of multiple cameras, including enhanced reliability through redundancy, comprehensive container coverage, enhanced durability, and versatility, make them a superior choice for ensuring smooth, efficient, and accurate container handling operations. While competitors may offer alternatives, the decision to prioritize the durability and reliability of multiple cameras ultimately provides a more cost-effective and dependable solution for port and terminal operations.

Want to learn more about our STS Crane OCR Solution?

About CERTUS STS Crane OCR

CERTUS Crane OCR automatically captures every container detail during loading and discharge without any impact to optimal spreader flights or the need of any extra illumination. The sophisticated image capture and recognition system is installed directly on the crane and integrates with the TOS system to ensure all captured data is instantly available for terminal operators.